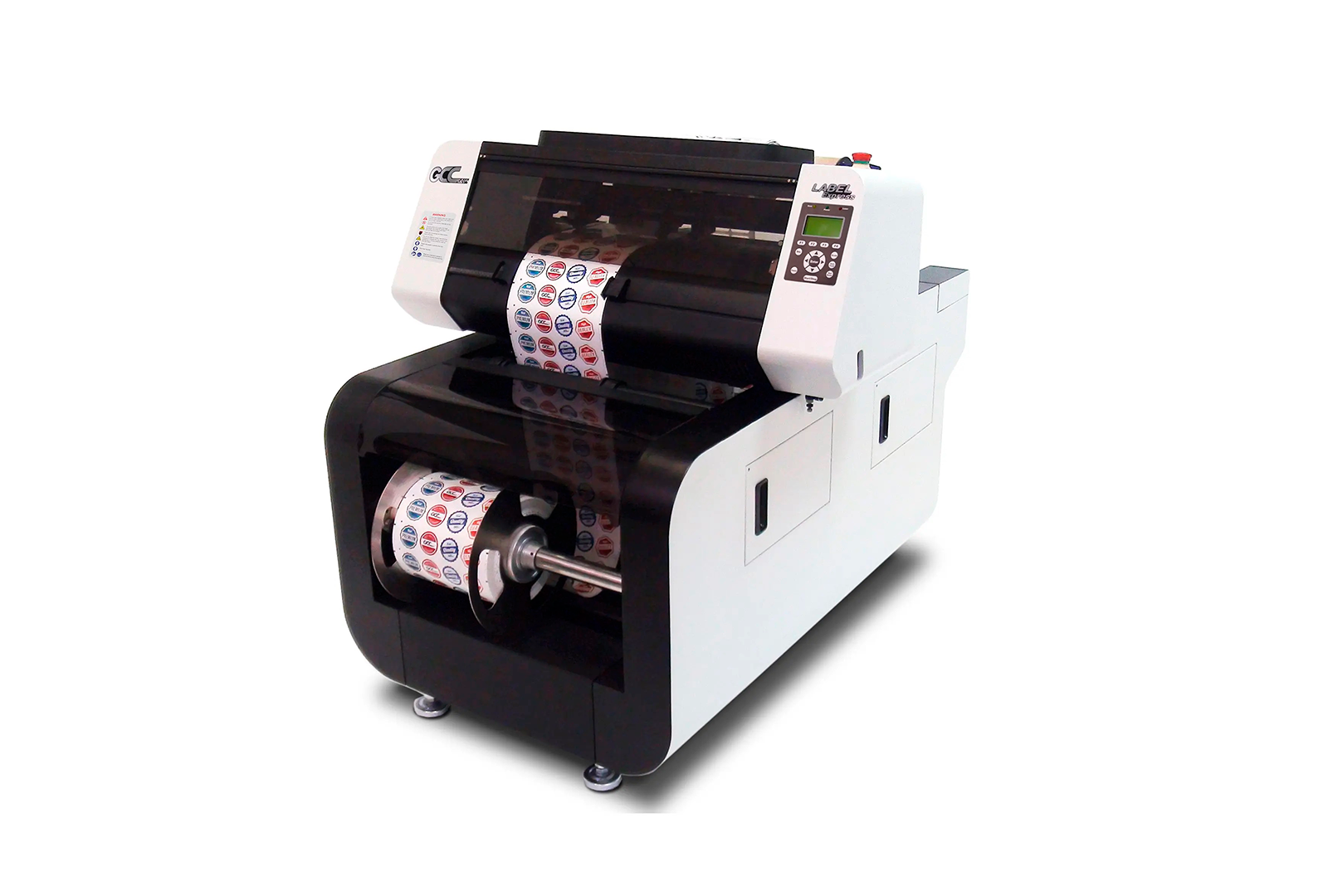

GCC Label Express

Laminator

With GCC Laminator + LabelExpress, you will be able to quickly and easily perform all these label finishing steps in a single, integrated and automated process:

Laminating(optional) / Laser Kiss Cutting / Laser Bridge Cutting / Slitting (optional) / Rewinding to finished rolls.

External Control Interface

The External Control Interface Board is an optional item that allows users to set up GCC machine for communication with external devices such as label printer and others to form an automatic production line.

Slitting Module

Slitting module is able to cut the roll media into smaller webs.

Paper Loading Cart

Paper loading cart is a handy tool that allows operators to put the media on the cart for the assembly of the media and the wind/rewind system.

Entry-Level Fume Extraction System

GCC PA-1500FS & PA-1000FS, CE-certified fume extraction systems, are designed to remove the hazardous fumes and dusts during laser processing to protect the health of operators, eliminate environmental pollution and enhance the laser cutting.

Air Compressor

A specially designed Air Compressor, by using an oil-less diaphragm, you help eliminate the harmful and damaging side effects of moisture on the laser optics. Also, provides the optimal air pressure your laser needs to blow away vaporized particles and helps prevents overheating. A must to keep lenses and mirrors clean to promote longer laser life.

| LabelExpress | LE15 | ||

| Model Number | LE15-20V93 | LE15-30V | |

| Cutting Width | 380 mm (15″) | ||

| Work Area (Sheet) (W x L) | 380 x 330 mm (15″ x 13″) | ||

| Max. Part Size (W x L x H) | Width | 400 mm (15.7″) | |

| Roll size | 76.2 mm (3″) core with 300 mm (11.8″) diameter | ||

| Laser Source | Sealed CO2 Laser | ||

| Wattage | 20W 9.3-μm | 30W 10.6-μm | |

| Drive | Closed-loop DC Servo Control | ||

| Roll to Roll | Stepper motor Control | ||

| Maximum Speed | 1,530 mm/s (60ips) (for straight line cutting) | ||

| Speed Control | Adjustable from 0.1~100 % (Up to 16 color-linked speed settings per job |

||

| Power Control | Adjustable from 0~100% ( Up to 16 color-linked power settings per job ) |

||

| Alignment System | CCD Module | ||

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | ||

| Computer interface | Standard USB port | ||

| Operating systems | MS Windows | ||

| Display Panel | 4-line LCD panel | ||

| Paper Feeding | Auto feed sensor, re-winding system, paper alignment control, waste removal system |

||

| Vacuum System | Down vacuum for media fixation | ||

| Top vacuum for media surface cleaning | |||

| Process materials | Paper, PET, PP, TNT, BOPP, etc. | ||

| Safety | Class IV Laser Product Compliant with EN60825-1:2014 Class IV Laser Product Compliant with CDRH |

||

| Dimensions (W x L x H) | Machine |

1,070 x 1,441 x 1,180 mm

(42.2 x 56.7 x 46.5 in.)

|

|

| Shipping | 1,320 x 1,660 x 1,490 mm (52 x 65.4 x 58.7 in.) |

||

| Weight | Machine | 250 kg | |

| Shipping | 362 kg | ||

| Facility Requirements | |||

| Electrical | 100~240 Volt AC, 50/ 60Hz, Auto Switching, Max. 10 Amp | ||

| Power Consumption | MAX:1000W | ||

| Optional (LabelExpress Laminator) | |||

| Lamination width | MAX: 380mm (15â€) | ||

| Lamination Film (outer diameter) | MAX: 250mm (9.8″), with core 76.2mm (3″) | ||

| Media (outer diameter) | MAX: 300mm (11.8″), with core 76.2mm (3″) | ||

*Specifications are subject to change without prior notice.